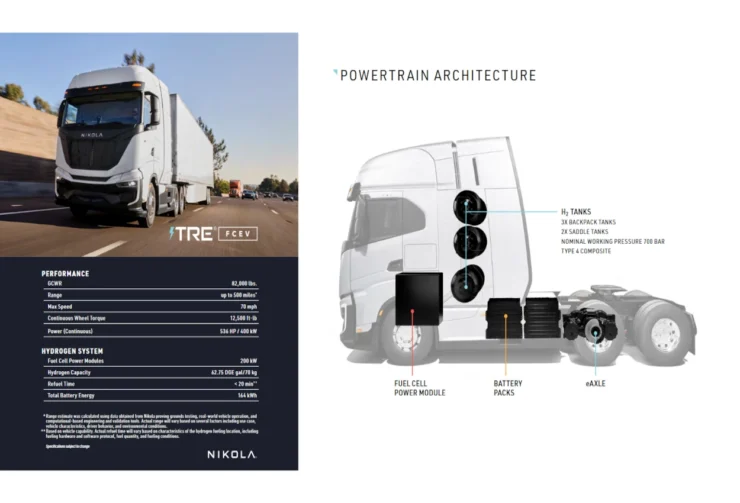

Nikola Trucks TRE FCEV or Hydrogen Electric Semi Trucks are Hydrogen Fuel Cell based Electric vehicles (FCEV). Below is a comprehensive exploration of the technical aspects, components, research breakthroughs, and collaboration efforts behind the Nikola TRE FCEV or Nikola TRE hydrogen trucks.

The Nikola TRE Fuel Cell Electric Vehicle (FCEV) represents cutting-edge technology in hydrogen fuel cell systems, vehicle energy management, and sustainable logistics. Nikola’s holistic approach to reducing carbon emissions combines innovation in materials, software, green hydrogen production, and strategic research and development (R&D) efforts.

1. Nikola Trucks TRE: Fuel Cell Stack and Key Components

Fuel Cell Stack Technology

The Nikola TRE FCEV features proton exchange membrane (PEM) fuel cells, designed for high efficiency and durability in heavy-duty trucking. Developed in collaboration with Bosch, the truck’s fuel cells deliver 240 kW of power through two 120 kW fuel cell stacks. This modular approach allows flexibility for different truck models, ensuring scalability across various payload and performance needs.

- MEA (Membrane Electrode Assembly): The core of the fuel cell stack, the MEA, facilitates the electrochemical process that splits hydrogen into protons and electrons. The protons pass through the proton-conducting membrane, while the electrons travel through an external circuit to power the electric motors.

- Catalyst Materials: Nikola and Bosch have developed an advanced catalyst coating made primarily of platinum. However, ongoing R&D aims to reduce reliance on platinum by researching nano material-based catalysts like graphene. This would lower costs while maintaining high catalytic efficiency.

- Bipolar Plates: These plates manage the flow of hydrogen and oxygen across the fuel cell, ensuring uniform distribution and preventing performance degradation. Lightweight materials like carbon composite are used to minimize the weight of the stack while maintaining strength.

Stack Efficiency and Longevity

The PEM fuel cells in the Nikola TRE achieve an efficiency rating of 60-65%, meaning a high proportion of the energy from hydrogen is effectively converted into electricity. The 700,000-mile lifespan is achieved through careful management of thermal stress and hydration of the proton-exchange membrane.

2. Nikola Trucks: Hydrogen Storage System and Refueling

Hydrogen Tanks

Hydrogen gas is stored as Compressed Gaseous Hydrogen (CGH2). The truck’s high-pressure hydrogen gas storage system consists of 700 bar carbon-fiber tanks capable of holding 70 kilograms of hydrogen. It has three backpack tanks and two saddle tanks, all of them made of Type 4 composite. This amount of hydrogen supports a driving range of approximately 500 miles on a full tank, making the Nikola Tre FCEV ideal for regional and long-haul applications.

- Tank Safety Features: The multi-layer construction of the tanks ensures resistance to punctures, temperature fluctuations, and pressure variations. Pressure relief valves and sensors continually monitor tank conditions to detect any anomalies.

- Fueling Infrastructure: The truck’s fast refueling capability is enabled by Nikola’s partnership with Nel ASA, which supplies the HYLA hydrogen stations. Refueling takes approximately 20 minutes, positioning the truck to compete with diesel vehicles in terms of operational downtime.

- Range: Up to 500 miles on a full hydrogen tank

- Hydrogen Capacity: 70 kg (total storage).

- Fuel Efficiency or mileage

- Hydrogen Consumption: ~7.14 miles/kg or 11.58 KM / Kg

- MPGe (Miles per Gallon Equivalent):: ~7.2 MPGe (based on energy equivalence: 1 kg H₂ ≈ 33.6 kWh).

- Notes: Hydrogen trucks are less energy-efficient than BEVs due to production and conversion losses but offer faster refueling and longer range.

3. Energy Management System (EMS) and Battery Integration

Hybrid Energy System:

The Nikola Tre FCEV includes two battery packs with a total usable capacity of 140 kWh (70 kWh each), which work in tandem with the fuel cell stack to power the vehicle. The battery packs can be charged, allowing the truck to operate in a plug-in hybrid mode for short distances without consuming hydrogen.

The truck’s powertrain integrates a 164 kWh lithium battery system to store excess energy generated by the fuel cells and regenerative braking. The energy management system (EMS) balances power output from the fuel cells and batteries, optimizing the truck’s efficiency during driving.

- Battery Chemistry: The high-performance battery system uses lithium-nickel-manganese-cobalt-oxide (LiNiMnCoO2) cylindrical cells, known for their energy density and ability to handle frequent charge/discharge cycles without significant degradation.

- R&D efforts are exploring solid-state battery technology, which could eventually replace traditional lithium-ion cells to improve energy density and safety.

Regenerative Braking

The regenerative braking system converts kinetic energy from deceleration into electrical energy stored in the battery. Nikola has engineered seven levels of regenerative braking, giving the driver control over energy recovery, reducing brake wear, and extending the truck’s driving range.

4. Nikola Trucks – Software Systems and Electronics

Energy Optimization Software

The Nikola TRE FCEV’s powertrain is governed by an advanced energy management system (EMS) that ensures the fuel cells and battery system work in harmony. The software analyzes driving conditions and energy demands, dynamically adjusting power distribution to maximize efficiency.

- Predictive Energy Distribution: The software can anticipate power needs based on terrain, load weight, and driving patterns, optimizing fuel cell output and battery utilization for maximum range.

5.Nikola Trucks: Telematics and Fleet Management

Nikola’s cloud-based telemetry and diagnostics system provides real-time monitoring of the truck’s performance, hydrogen consumption, battery health, and overall system integrity. Fleet managers can access this data remotely to enhance operational efficiency and schedule preventative maintenance. The system also supports over-the-air (OTA) updates, ensuring that the latest software enhancements are always installed.

Driver Assistance Systems (ADAS)

The truck features a suite of Advanced Driver Assistance Systems (ADAS), including:

- Adaptive Cruise Control (ACC)

- Lane Departure Warning (LDW)

- Blind-Spot Monitoring

- Autonomous Emergency Braking (AEB)

These systems enhance driver safety and comfort, particularly during long-haul operations, reducing the risk of accidents and improving road safety.

6. Green Hydrogen Production and Infrastructure

Partnership with Nel ASA

Nikola has partnered with Nel ASA, a leading hydrogen technology company, to establish green hydrogen refueling infrastructure across key transport routes. Hydrogen for Nikola trucks is produced via electrolysis, a process that uses renewable electricity from solar, wind, and hydropower to split water into hydrogen and oxygen.

- Green Hydrogen: Electrolysis produces hydrogen with zero carbon emissions, ensuring that the fuel used in Nikola trucks is entirely renewable. The goal is to establish a comprehensive network of HYLA hydrogen stations, with plans to build 700 stations by 2028, allowing fleets to operate entirely on green hydrogen.

R&D in Hydrogen Production

Nel ASA and Nikola are exploring next-gen electrolysis technology, focusing on improving efficiency, reducing water consumption, and lowering overall production costs. Solid oxide electrolysis (SOEC) technology is also being researched, which operates at higher temperatures to increase hydrogen production efficiency by utilizing waste heat from industrial processes.

7. Strategic Partnerships and Collaborations

- Bosch: A major partner in the development of fuel cells, electric motors, and power electronics. Bosch’s role is central to the truck’s core components, especially in optimizing fuel cell stacks for mass production.

- IVECO: Nikola’s collaboration with IVECO enables production at their Ulm, Germany facility, which serves as the main hub for European truck manufacturing.

- Nel ASA: Provides critical infrastructure for green hydrogen production and refueling, with an aim to build a global network of HYLA hydrogen stations.

Conclusion

The Nikola TRE FCEV is a pivotal player in the transition to zero-emission heavy-duty transportation, leveraging cutting-edge hydrogen fuel cell technology, integrated battery systems, advanced software, and green hydrogen infrastructure. Through its partnerships with Bosch, IVECO, and Nel ASA, Nikola is driving innovations in both vehicle technology and hydrogen production.

Source: https://www.nikolamotor.com/

This article is Copyright protected

Add comment